Introduction:

Offshore wind energy (OWE) is rapidly gaining momentum as a sustainable and environmentally friendly power source. With governments and industries worldwide working towards a greener future, it's essential to understand the material requirements and sustainability challenges associated with OWE development. In this blog post, we'll explore the paper "Future material requirements for global sustainable offshore wind energy development" and discuss the main findings, potential solutions, and what it means for the future of OWE.

Global Offshore Wind Energy Outlook:

According to the International Energy Agency (IEA), in 2019, offshore wind had a total capacity of 23 GW and accounted for 0.3% of global power generation. The IEA projects a strong growth in installed OWE capacity, with a likely doubling by 2025, and a total of 342–560 GW by 2040. As offshore wind energy expands, it's crucial to examine the resources needed for its development and the potential impacts on the environment.

Material Requirements for Offshore Wind Energy Development:

The paper highlights that exploiting OWE will require significant quantities of raw materials from 2020 to 2040. The materials could include 129–235 million tonnes (Mt) of steel, 8.2–14.6 Mt of iron, 3.8–25.9 Mt of concrete, 0.5–1.0 Mt of copper, and 0.3–0.5 Mt of aluminum. Moreover, substantial amounts of rare earth elements will be required towards 2040, adding to the complexity of sustainable OWE development.

As wind turbines increase in size and are placed further offshore, the demand for materials like low-alloyed steel also grows, primarily for constructing support structures like towers and foundations. Between 2020 and 2040, the sustainable development using advanced technology (SD-AT) scenario estimates a cumulative demand of 192.9 Mt of low-alloyed steel, 8.8 Mt of high-alloyed steel, 12.9 Mt of iron, and 13.4 Mt of concrete. The demand for key metals (Cu, Al, Cr, Mn, Mo, Ni, and Zn) is projected to grow from 2 Mt in 2020-2030 to 3.7 Mt in 2030-2040. Additionally, by 2040, there will be a significant requirement for rare earth elements (REEs) like Nd, Dy, Pr, and Tb, used in permanent magnet-based generator technologies.

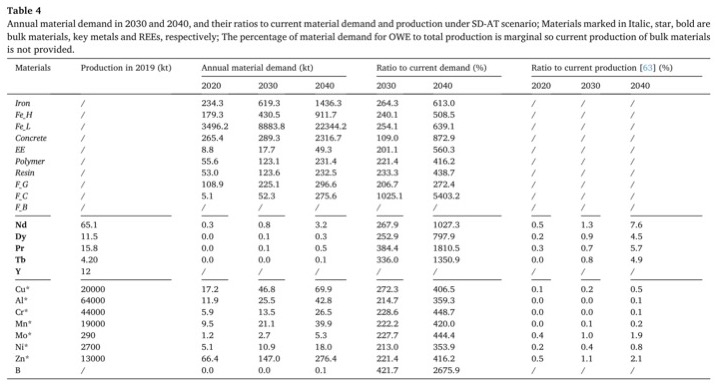

Table 4 below compares the annual material demand in 2030 and 2040 to the current demand and production. The demand for bulk materials and key metals is expected to increase by two orders of magnitude from 2020 to 2030, and by over twofold from 2030 to 2040. However, the demand for REEs for OWE in 2030 and 2040 is only 3% and 11% of the REE supply in 2020, respectively. The passage highlights that there may be competition for REEs from other sectors with fast-growing demand, such as electric vehicles, onshore wind power, solar, electronics, and industrial robots.

The SD-AT has higher OWE installed capacities than the SP (state policy) scenario, which translates to higher material demand. The SD-AT requires 95 Mt more bulk materials, 3.2 Mt more key metals, and 17.0 kt more REEs cumulatively between 2020 and 2040 compared to the SP scenario. The demand for Cu, Al, and steel decreases in the AT scenario and declines even further in the NT (new technology) scenario compared to the baseline CT (conventional technology) scenario. The AT and NT scenarios require more concrete but less steel than the baseline (CT) due to the growth of hybrid tower concepts and a reduction of monopile foundations.

Overall, bulk materials represent the primary mass demand for future OWE technologies, with steel accounting for around 82% of the demand. The foundation requires most of the low-alloyed steel, followed by the tower. Most of the iron, high-alloyed steel, copper, and aluminum are used in the nacelle, and the requirements for REEs largely originate from the nacelle due to the rising market shares of PM-based generator technologies.

However, it should be noted that this paper is specific to offshore wind, and offshore wind currently makes up roughly 7% of total wind power generated where wind will make up only a fraction of the total energy supplied, meaning these material requirements are for a technology that will make up approximately 2-3% of total energy generation by 2040.

Recycling and Lifetime Extension of Wind Turbines:

Closed-loop recycling can help supply secondary materials for offshore wind energy (OWE) development and mitigate material criticality. Under the studied recycling scenario, 3% and 12% of material requirements for OWE can be obtained via closed-loop recycling between 2020-2030 and 2030-2040, respectively. The proportion of recyclable materials is expected to increase as more wind turbines reach the end of their lifetime. Wind turbines are on average 85% recyclable, but there is currently a lack of circular design approaches to maximize recycling potential. Rare earth elements (REEs) are of high economic importance with high recycling potential, but few projects have reached desirable scales due to technical challenges. Wind turbine rotors, which are made of composite materials, are difficult to recycle due to their composition. To expand the use of recycled materials, recycling chains need to be better understood in terms of economic value, physical separation, concurrent materials requirements, and design optimization tools. Additionally, extending the lifetime of wind turbines from 20 to 25 years could help reduce material requirements by 7–10%.

Conclusion:

The rapid growth of offshore wind energy presents both opportunities and challenges for sustainable development. Understanding the material requirements for OWE is crucial to ensure that its expansion does not negatively impact the environment. Strategies such as closed-loop recycling and extending the lifetime of wind turbines can help address these challenges, paving the way for a greener and more sustainable future. While the material requirements are small for specifically OWE, this is only a small fraction of material requirements across solar, wind, EVs, electronics, power supply and storage, among other needs to hit current sustainable targets.